Fume extraction system for Induction Furnaces

Induction furnaces are an important part of the steelmaking process, as they allow steel producers to quickly and efficiently melt down scrap metal and ore. However, induction furnace processes can produce fumes that can contain dangerous pollutants, necessitating the use of hoods for fume collection and cleaning. In this article, we will discuss the induction furnace process, the types of pollutants present in the fume exhaust, and the different hoods available for fume collection and cleaning.

Induction Furnace Processes

Induction furnace processes involve heating metal ore or scrap by passing an electrical current through it. The electrical current creates an electromagnetic field which induces eddy currents in the metal, producing intense heat in a short amount of time. The process requires precise temperature control, careful monitoring of the furnace’s power input, and the periodic addition of fluxing agents.

The induction furnace process is typically used to melt scrap metal and ore for the production of steel and other alloys. Induction furnaces are capable of reaching temperatures of up to 2,500°C, much higher than other furnace types, allowing for the production of a wide range of steels and alloys. The induction furnace process is significantly more efficient than other types of furnace processes, allowing for rapid cooling and production of high-quality steel.

Fume Extraction System for Induction Furnace

The induction furnace process produces a significant amount of fume exhaust, which can contain a number of dangerous pollutants. The contaminants in the exhaust can include particulate matter, such as smoke and dust, as well as toxic chemicals and heavy metals. Particulate matter can be dangerous to humans when inhaled, while toxic chemicals and heavy metals can cause long-term health effects.

In order to protect workers and the surrounding environment from these pollutants, it is necessary to collect and clean the fume exhaust. This can be done with the use of hoods, which are designed to capture and contain the exhaust before it is released into the environment.

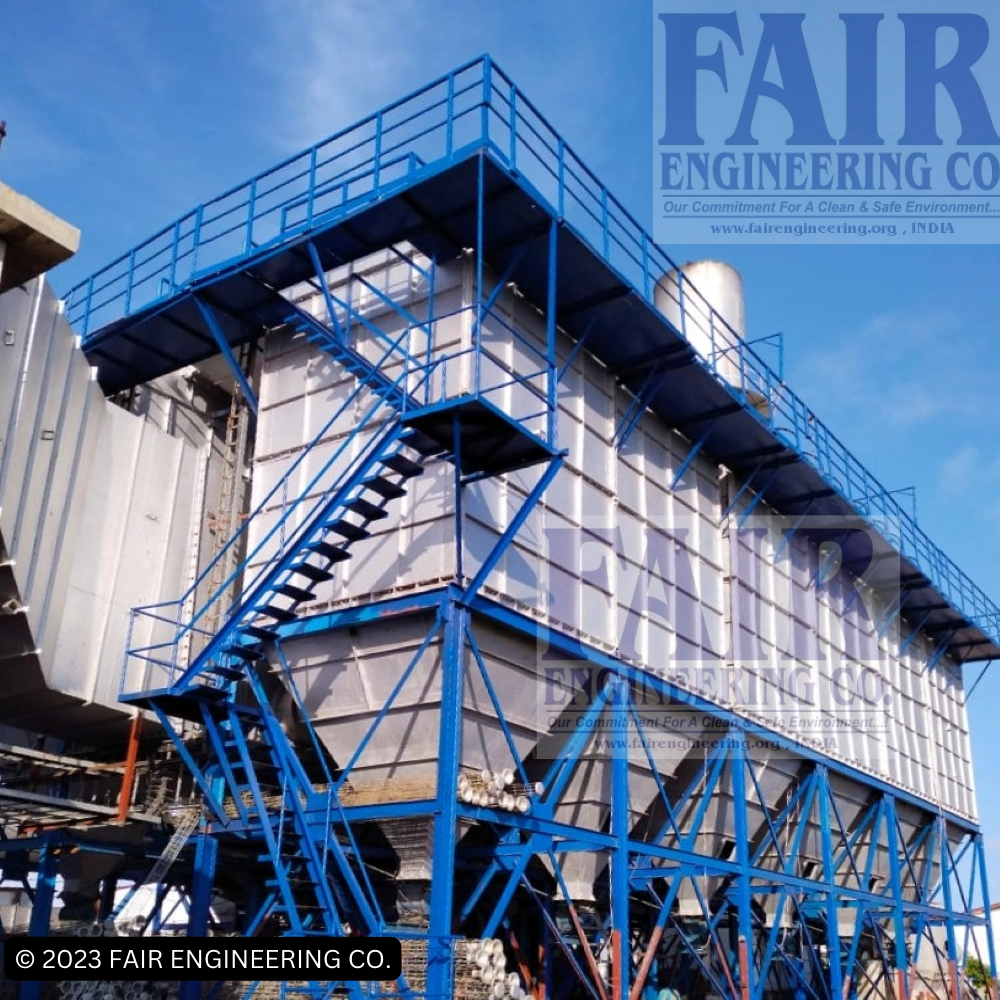

Fair Engineering Co. (FEC’s) designed Ind-FES system which is useful to capture high temperature fumes emanating from Induction furnace which are sucked from the furnace via canopy hoods or side draft hoods.

During extracting of the fumes, it contains very high temperature which needs to be cooled down. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3.

Finally, proper maintenance of the air pollution control system is essential for ensuring the system is working properly and providing adequate air pollution control. This includes regular cleaning of the system components, regular testing, and replacement of worn parts, as well as scheduled maintenance of all components.

Stay Connected with Fair Engineering Company by subscribing to our youtube channel. You can also mail us at info@fairenggcompany.com for any queries releated to FES System.

Fume extraction system for Argon Oxygen Decarburizer (AOD)

To control air pollution emanating from AOD furnaces, use an appropriate air pollution control system which includes devices such as scrubbers, baghouses, or electrostatic precipitators, cyclones, high efficiency blowers to capture and remove pollutants from the furnace exhaust. The use of most appropriate filter media can help reduce the amount of dust and particulate matter in the exhaust.

Fume Extraction System for AOD

Fair Engineering Co. (FEC’s) designed FES system is useful to capture high temperature fumes emanating from AOD by placement of the water-cooled primary hood provided over the AOD vessel. Water-cooled ducting is provided to channelise the fumes to bag filter system. To help in movement of Overhead crane, pouring of molten metal from ladle the furnace needs to be tilted often, hence FEC has designed moveable hood and ducting on trolley, thereafter a fixed water-cooled duct with a fixed specified gap between secondary hood elbow flange and duct is made to facilitate fume suction. The water-cooled ducting can be of double walled or tubular design types.

During AOD working process the exhaust fume temperature is about 1200°C which needs to be cooled down up to 140°C. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3

In conclusion, air pollution control from AOD furnaces is an important process that requires careful attention, as many of the pollutants released by these furnaces are hazardous to human health. By ensuring the FES system is properly maintained and by upgrading system spare parts after service life, can help reduce the amount of air pollution produced by AOD furnace.

Do you have high turnaround times, pollution issues and labor health concerns impacting your business revenues?

Consult our experts for your pollution control issues!

Fume Extraction system for Laddle Refining Furnace (LRF)

One major challenge that steel plants face is the capture and management of fumes produced during the refining process. Liquid refining furnace (LRF) fume capture systems are an important part of the overall safety and management of steel production.

LRF fume capture systems are designed to capture the fumes generated during the liquid refining process. The fumes are typically generated as a by product of the extremely high temperatures used to refine the steel. The fumes contain hazardous particles and volatile organic compounds (VOCs) that can be dangerous to workers and the environment. The LRF fume capture system captures these fumes and prevents them from entering the air.

The LRF fume capture system typically consists of a series of hoods fitted around the LRF fume escape point that collect the particles and VOCs. The hoods are connected to axial fans that then pushes the fumes into the water-cooled ducting system. From there, the fumes are carried towards a filtration system which is cleansed and released back into the atmosphere. The system is designed to be automated, meaning that the operator does not have to continually monitor the system.

Fume Extraction System for LRF

Fair Engineering Co. (FEC’s) designed LRF-FES system which is useful to capture high temperature fumes emanating from LRF which are sucked from the furnace. Water-cooled ducting is provided to convey the fumes. The water-cooled ducting can be of double walled or tubular. The tubular ducting will have longer life as proper water conveying velocities can be maintained as there will be no short circuiting of water unlike in the double walled water-cooled ducts. It is necessary to have treated cooling water circulation in water-cooled circuit. The water must be treated for TSS, TDS and hardness etc.

During extracting of the fumes, it contains very high temperature which needs to be cooled down. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3.

Finally, proper maintenance of the air pollution control system is essential for ensuring the system is working properly and providing adequate air pollution control. This includes regular cleaning of the system components, regular testing, and replacement of worn parts, as well as scheduled maintenance of all components.

Overall, the use of LRF fume capture systems is essential for safe and efficient steel production. The filters capture potentially harmful fumes and prevent them from entering the air, while also helping to reduce emissions and increase the efficiency of the refining process. With the proper use of LRF fume capture systems, steel plants can ensure that the steel produced is of the highest quality and safe for use.

Fume Extraction system for Electric Arc Furnace (EAF)

Fume Extraction System for EAF

Fair Engineering Co. (FEC’s) designed FES system which is useful to capture high temperature fumes emanating from EAF are sucked from the water-cooled elbow provided on its 4th hole. Water-cooled ducting is provided to convey the fumes. A suitable water-cooled moving sleeve or alternatively a fixed water-cooled duct with a fixed specified gap between elbow flange and duct can be made to facilitate the EAF roof movements. The water-cooled ducting can be of double walled or tubular. The tubular ducting will have longer life as proper water conveying velocities can be maintained as there will be no short circuiting of water unlike in the double walled water-cooled ducts. It is necessary to have treated cooling water circulation in water-cooled circuit. The water must be treated for TSS, TDS and hardness etc.

During extracting the fumes, it contains very high temperature which needs to be cooled down. The dust concentration in the fume is in the order of 2 to 3g/Nm3. The initial fumes coming out from the AOD will be cooled down by water cooled ducting, later it will be cooled down by Forced Draft Cooler (FDC) to suit the temperature for filter bags and protect them from burning. Once the desired temperature reduction is achieved, the fumes will be directed towards bag filter and then fumes will get filtered up to concentration level of less than 50mg/Nm3.

In conclusion, air pollution control from EAF furnaces is an important process that requires careful attention, as many of the pollutants released by these furnaces are hazardous to human health. By ensuring the FES system is properly maintained and by upgrading system spare parts after service life, can help reduce the amount of air pollution produced by EAF furnace.